Technologies

Process Features

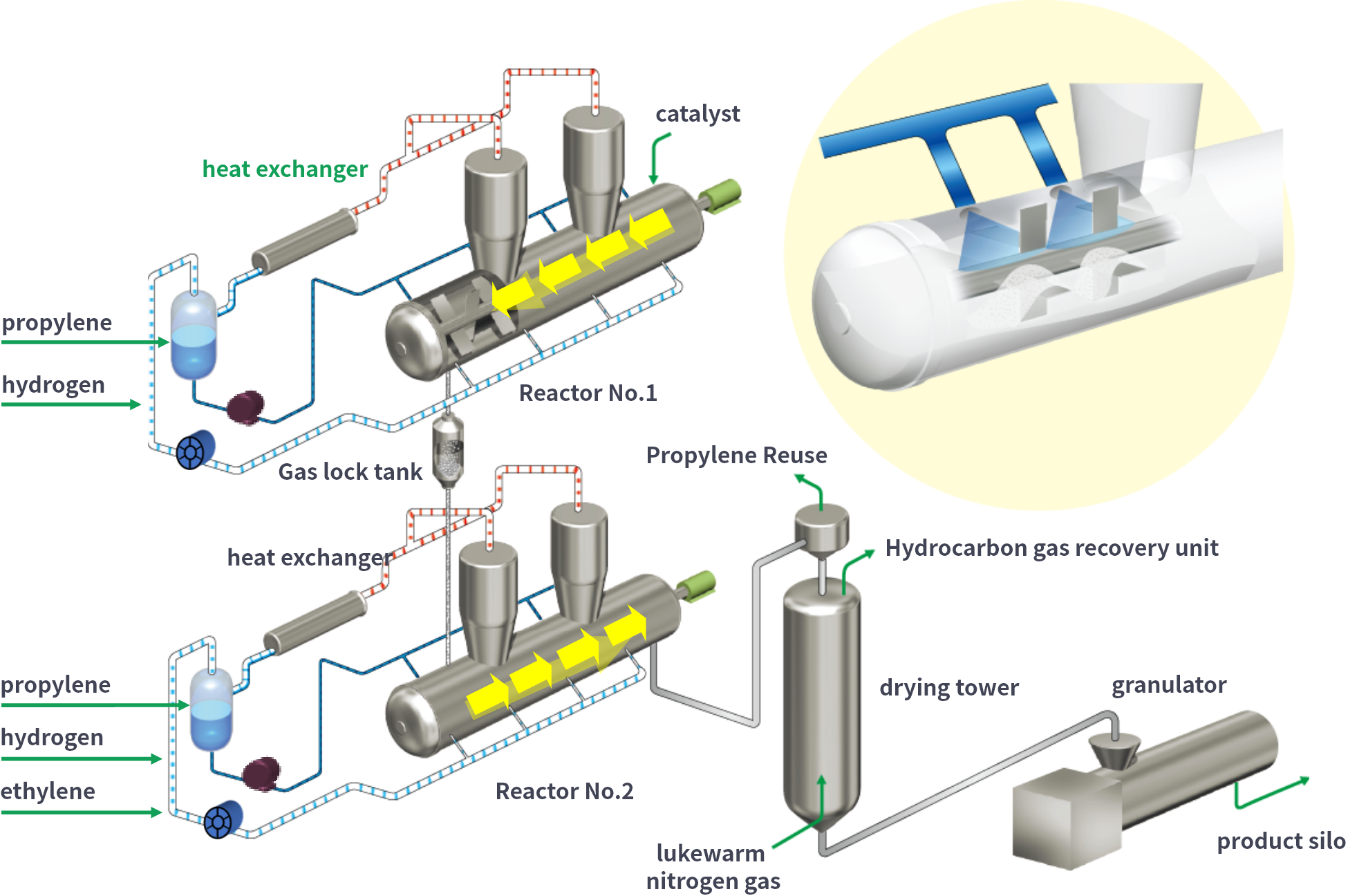

The JPP Horizone™ Process, which is characterized by its long horizontal reactors, ensures uniform residence time distribution of catalyst particles in the reactor, maximizes catalyst performance, and provides an optimal reaction heat removal environment, resulting in stable plant operation and high-quality product production.

The efficient reaction heat removal system, which utilizes the latent heat of evaporation of liquid propylene and is finely controlled in each of the multiple zones, prevents the formation of lumps in any type of product and realizes precise reaction temperature control.

JPP Horizone™ Process

- A simple mechanism gas-phase polymerization process, with horizontal reactors placed in two stages, each of which is gently mechanically agitated at low speed to realize advance the polymerization reaction.

- Removal of polymerization reaction heat is accomplished by evaporation of liquid propylene sprayed onto the powder layer, and the temperature of the powder layer is precisely controlled well.

- By adjusting the polymerization ratio of the first and second stages, many excellent products with a wide range of ethylene-propylene compositions can be produced, especially IMPACT COPOLYMER and NEWCON.

Catalyst Technology

The tailor-made JPP catalyst for the JPP Horizone™ Process is designed to contain a rich rubber content with minimal fines, ensuring optimum powder flow in the process while minimizing adhesion and powder adhesion to the vessel. These features enable the JPP Horizone™ Process to operate stably over the long term.