Solution

We will introduce our efforts to achieve carbon neutrality and circular economy of polypropylene through our proposals for environmentally friendly components and environmentally friendly packaging.

The contents of this page will be updated as needed.

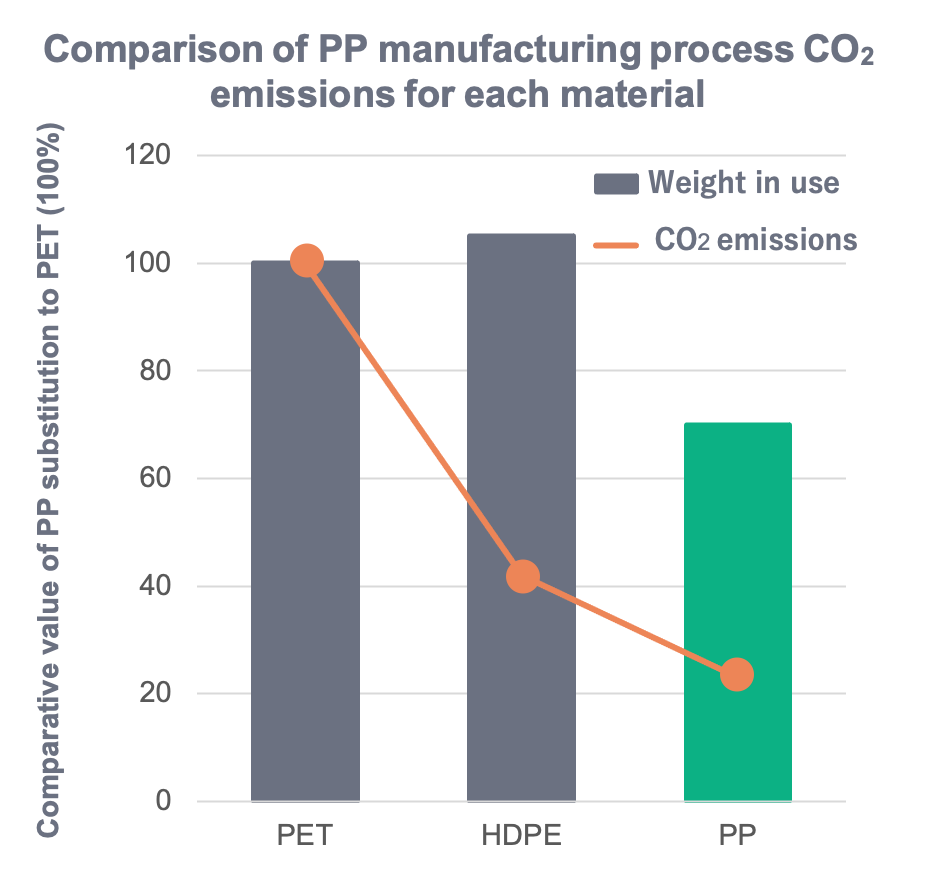

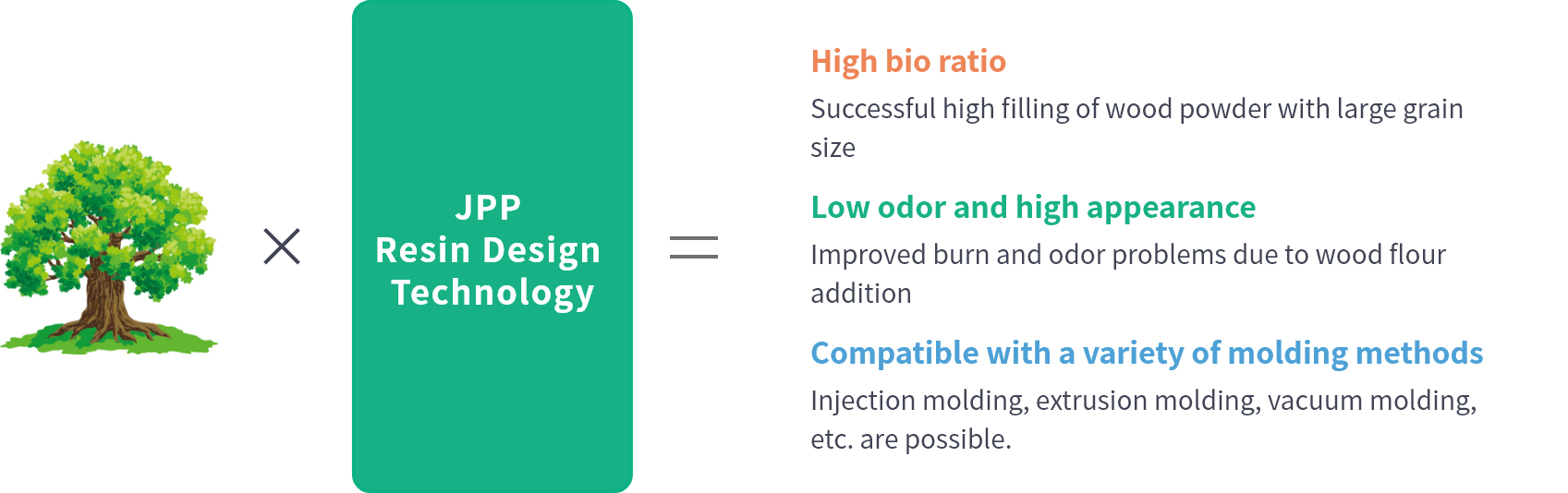

PP Utilizing Natural Materials

With the recent demand for CO2 emission reduction, biocomposites, in which biomass materials are composited into resins, are attracting attention.

We will contribute to solving issues in manufacturing biocomposites by using PP for biocomposites such as high flow, low melting (WINTEC︎™) polypropylene and WAYMAX™︎, which can contribute to expanding product applications.

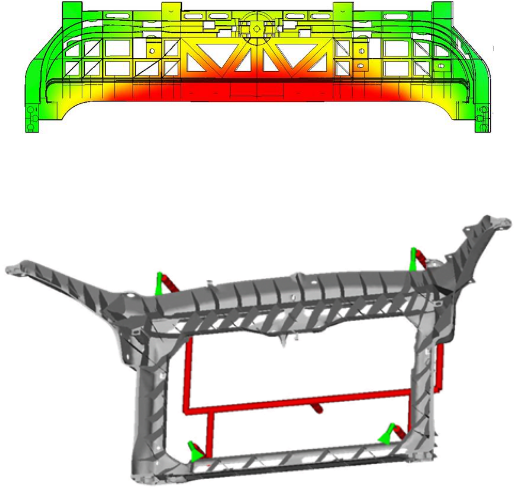

Contributing to Automobile Weight Reduction

We develop and propose "lightweight and highly rigid materials" that can contribute to the reduction of CO2 emissions from automobiles and to the extension of cruising range due to the shift to EVs and other environmental measures.

Glass Long Fiber Reinforced Polypropylene

FUNCSTER™ (Long glass Fiber reinforced Thermoplastics)

FUNCSTER™is a high quality "LFT (Long glass Fiber reinforced Thermoplastics)" made by our original pultrusion method.

Features

In addition to high strength, FUNCSTER™ has "high flow" and "high appearance" and aims to reduce environmental impact by eliminating painting.

Specific strength is about 3 times that of steel, and 20-40% weight reduction is possible.

Application to large products/functional parts

CAE analysis (structural/flow)

Proposal for

optimal lightweight structure

High melt-tension PP (WAYMAX™)

Examples in the Food Container Field

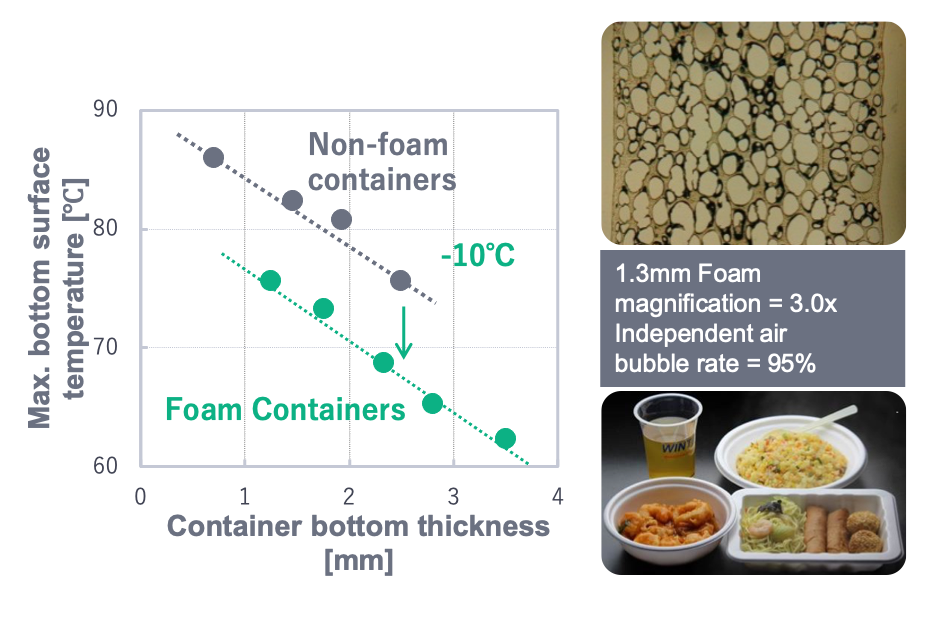

In the field of food containers, demand for foamed materials is increasing.

Foam containers, which can be held in the hand after microwaving without worrying about the heat of the contents and also retain heat, continue to be adopted for a variety of applications, including take-out and delivery to convenience stores and box lunch stores.

They are also extremely environmentally friendly materials with a significantly reduced amount of resin.

Japan Polypropylene Corporation’s WAYMAX™ has high melt strength and strain-hardening properties during melt-extension, which results in the formation of fine, uniform independent air bubbles and enables it to achieve high heat insulation properties and the necessary physical properties for containers.

WAYMAX™ Foam Containers

- Improved foaming ratio

- Uniform and fine bubbles

- High independent bubble ratio

Example of injection foaming

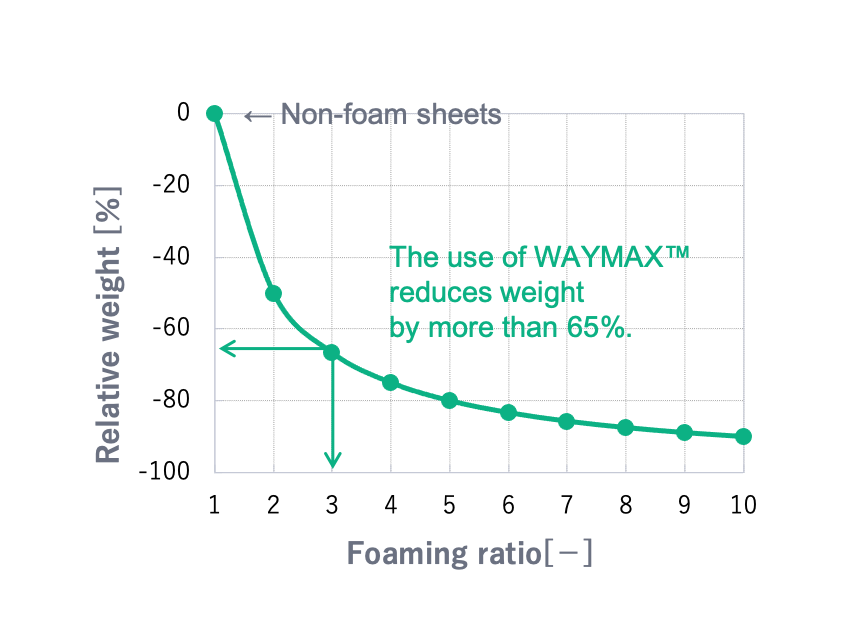

With the tightening of environmental regulations, there is a growing need to reduce vehicle weight in order to reduce CO2 emissions.

Injection foamed molded products using WAYMAX™ form fine and uniform independent air bubbles, enabling the production of molded products with a higher appearance than ever before.

In addition, the apparent density is reduced, so not only can the amount of material used be reduced, but molded products can also be made lighter and have higher heat insulation and sound insulation properties.

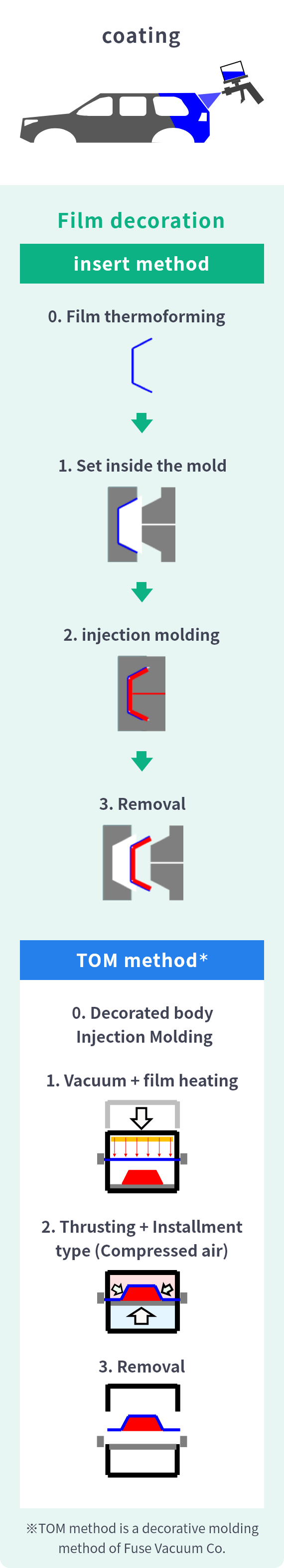

Decorative film (application of film using WAYMAX™ material)

Decorative film capable of decorating complex shapes. It is adhesive-free and can be firmly adhered to polypropylene-based moldings, providing excellent appearance. The all-PP process eliminates the need for separation of coated film fragments and facilitates recycling of decorated products, thereby contributing to waste reduction. It is also an environmentally friendly material because no solvents are used.

Paintless (adhesive-free & solvent-free) → All PP can be used for decorative moldings

Examples in the film field

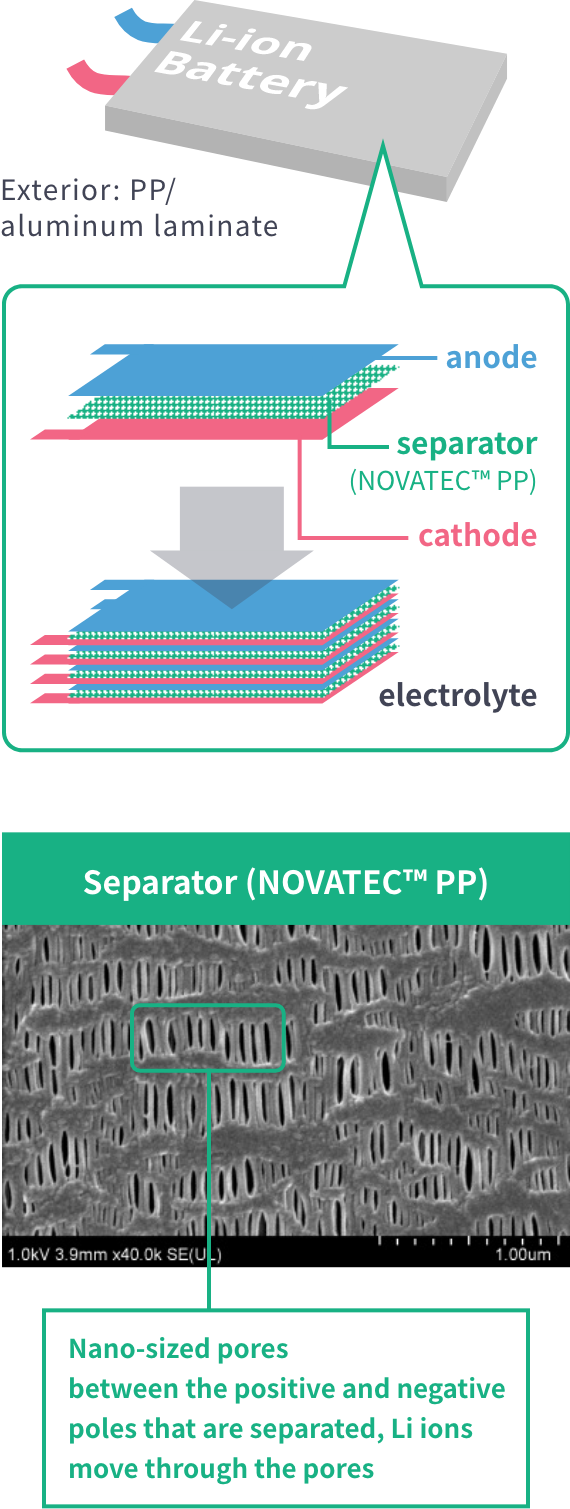

Films for electronic materials (NOVATECTM PP : expansion into battery materials)

NOVATEC™︎ PP is also suitable for lithium-ion battery components, which require compatibility with special processing and cleanliness, and can combine cutting-edge high functionality with reduced environmental impact.