What is NOVAORBIS™?

The “NOVAORBIS™” brand of polyethylene and polypropylene products provided by Japan Polyethylene Corporation and Japan Polypropylene Corporation is a brand name for polyethylene and polypropylene products made from raw materials that have a low impact on the environment, as opposed to conventional products made from fossil fuels.

“NOVAORBIS™” is one of the specific measures of HOPE&LOOPP™, the landing symbol for the overall low-environmental-impact activities of the NIPPON POLYCHEM Group, and this product is an important step towards a sustainable future.

Born from the technical capabilities and commitment to sustainability of Japan Polyethylene Corporation and Japan Polypropylene Corporation, “NOVAORBIS™” offers a new option for the industry.

NOVAORBIS™ PP Product line

|

|

|---|---|

|

|

The idea behind NOVAORBIS™

Both "NOVA" and "ORBIS" are derived from Latin, meaning "new" and "world," respectively, and "NOVAORBIS" represents the "New World.

The name represents a fresh perspective and innovative approach in the plastics industry, with a focus on sustainable advanced materials that have the potential to reshape the market.

The NOVAORBIS™ logo represents sustainable growth and futurism.

The wavy green at the center of the ring-shaped regular circle represents an abstract leaf. The blue on each side represents a rotating movement, indicating circulation and sustainable cycles.

NOVAORBIS™-MR

Evolving Quality, Safe Recycled Polypropylene

We provide mechanical recycled polypropylene that has been made high-performance through our material design technology.

We have a lineup that can be used for various purposes, such as Automotive & Appliance Products Applications and Living & Consumer Products Applications.

Physical properties [Mechanical Recycled Polypropylene] NOVAORBIS™-MR

- This is a typical data, not to be construed as specification.

- Application suitability should be confirmed with the final product by referring to the physical property values.

NOVAORBIS™-CR

High-Quality Recycled Polypropylene reborn through Next-Generation Recycling Technology

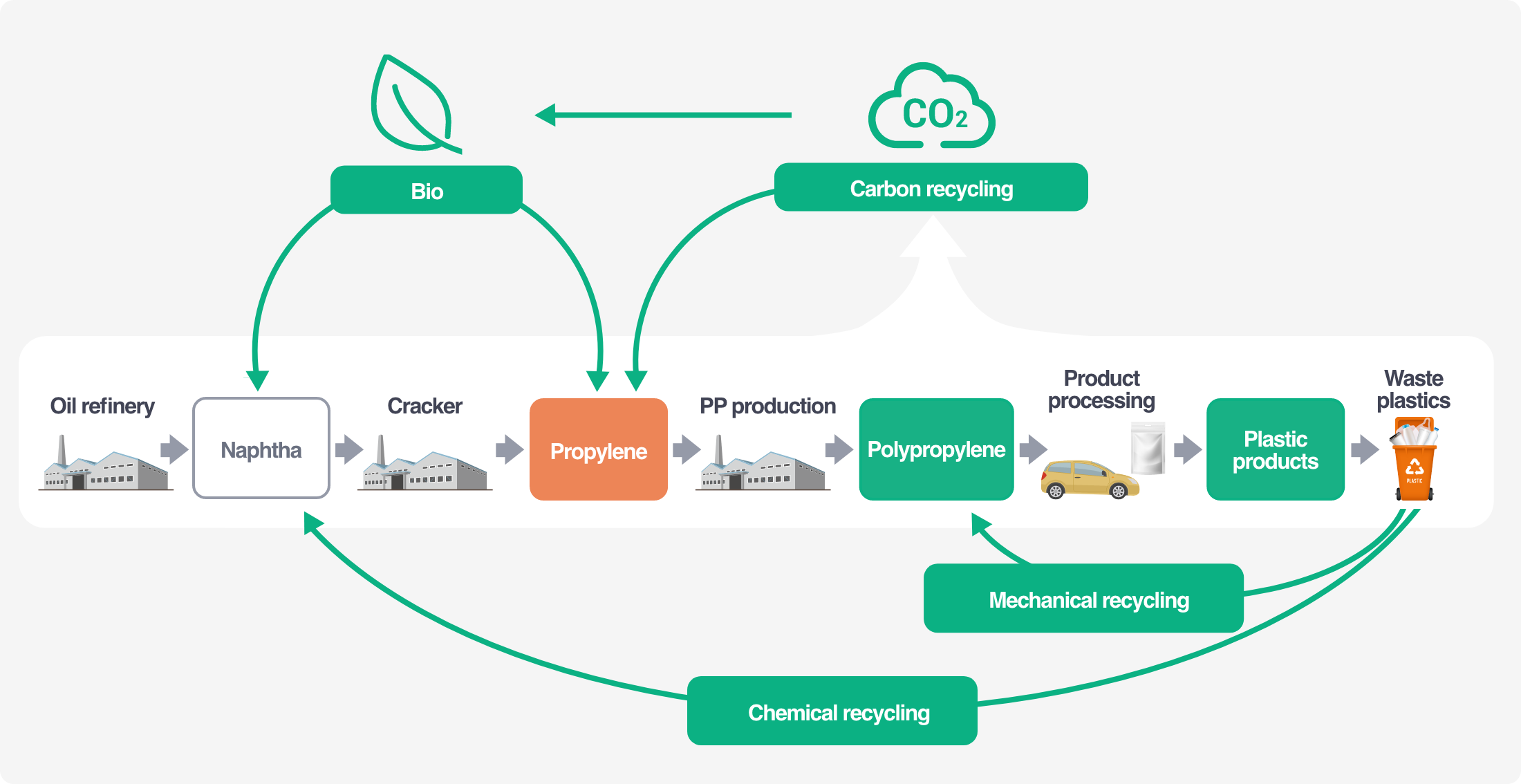

We will consider manufacturing and selling chemical-recycled PP using chemical-recycled propylene (mass balance method) obtained by the oil conversion technology of waste plastics.

We will actively work to create a closed loop in order to realize a circular economy.

NOVAORBIS™-CU

CO₂-Recycling Polypropylene created together with the Earth

It is created from sunlight, water and CO₂, and while maintaining the high functionality of PP, it recycles CO₂ generated from human activity and puts it to use again.

This initiative is the first of its kind in the world, and it aims to achieve a permanent cycle of CO₂ within the life cycle of PP products, from manufacturing to disposal.(currently being considered for commercialization by Mitsubishi Chemical Corporation)

NOVAORBIS™-BP

Polypropylene that Contributes to Carbon Neutrality through the Power of Plants

We are planning to manufacture and sell polypropylene using propylene obtained from bionaphtha (mass balance method).

We will also consider the production and sale of polypropylene using propylene obtained from bioethanol.(currently being considered for commercialization by Mitsubishi Chemical Corporation)

We are considering using this product not only with the mass balance method, but also with the segregation method.